Ukukhetha iingxowa zeplastiki eziguquguqukayo kunye neefilimu phezu kwezikhongozeli zemveli ezifana neebhotile, iingqayi, kunye nemigqomo kunika iingenelo ezininzi:

Ubunzima kunye nokuphatheka:Izingxobo ezithambileyo zikhaphukhaphu kakhulu kunezikhongozeli eziqinileyo, nto leyo eyenza kube lula ukuthuthwa nokuphatha.

Ukusebenza kweSithuba:Iipowutshi ziyakwazi ukucandwa xa zingenanto, okonga indawo yokugcina kunye nangexesha lokuhamba. Oku kunokukhokelela kwiindleko zokuthumela eziphantsi kunye nokusetyenziswa ngokufanelekileyo kwendawo yeshelufu.

Ukusetyenziswa kwezinto:Ukupakishwa okuguquguqukayo ngokuqhelekileyo kusebenzisa izinto ezincinci kunezikhongozeli eziqinileyo, ezinokunciphisa impembelelo yokusingqongileyo kunye neendleko zemveliso.

Ukutywinwa kunye nokuTsha:Iipowutshi zinokutywinwa ngokuqinileyo, zibonelela ngokhuseleko olungcono kubumanzi, emoyeni, nakwizinto ezingcolisayo, ezinceda ukugcina ukutsha kwemveliso.

Ukulungiselela:Ukupakishwa okuguquguqukayo kunokwenziwa ngokulula ngokwemiqathango yobungakanani, imilo, kunye noyilo, okuvumela ukuthengisa ngobuchule obungakumbi kunye namathuba okuthengisa.

Ukhetho lwezixhobo eziqhelekileyo:

Irayisi / ipasta ukupakishwa:PE/PE,Iphepha/CPP,OPP/CPP,OPP/PE,OPP

Ukupakishwa kokutya okuMkhenkce:PET/AL/PE,PET/PE,MPET/PE,OPP/MPET/PE

Ukupakishwa kweSnacks/Chips:OPP/CPP,OPP/OPP Isithintelo,OPP/MPET/PE

Iibhiskithi kunye nokupakishwa kwetshokholethi:I-OPP iyanyangwa,OPP/MOPP, PET/MOPP,

Ukupakishwa kweSalami kunye neCheese: Ifilimu yeLids iPVDC/PET/PE

Ifilimu esezantsi (itreyi)PET/PA

Ifilimu esezantsi(itreyi)LLDPE/EVOH/LLDPE+PA

Iisuphu/iisosi/ipakethe yeziqholo:PET/EVOH,PET/AL/PE,PA/PE,PET/PA/RCPP,PET/AL/PA/RCPP

Iindleko-Ngempumelelo:Iindleko zemveliso kunye nezinto eziphathekayo zeengxowa eziguquguqukayo zihlala zingaphantsi kunezo zikhongozeli eziqinileyo, nto leyo ezenza zibe lukhetho olunoqoqosho ngakumbi kubenzi.

Ukurisayikilisha:Iifilimu ezininzi zeplastiki ezibhetyebhetye kunye neengxowa ziyakwazi ukuphinda zisetyenziswe, kwaye ukuqhubela phambili kwemathiriyeli kubenza bazinze ngakumbi.

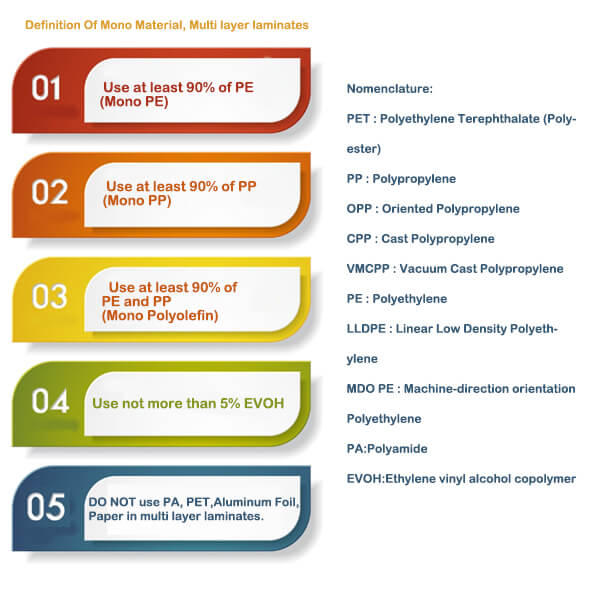

Ukuphinda kusetyenziswe ukupakishwa kweplastiki kubhekiselele kubuchule bemathiriyeli yeplastiki ukuba iqokelelwe, ilungiswe, kwaye isetyenziswe kwakhona ekuvelisweni kweemveliso ezintsha. Inkcazo eyamkelekileyo kwihlabathi jikelele iquka imiba engundoqo emininzi:Ipakethe kufuneka iyilwe ngendlela eququzelela ukuqokelelwa kwayo kunye nokuhlelwa kwiindawo zokurisayikilisha. Oku kuquka iingqwalaselo zokuleyibheli kunye nokusetyenziswa kwemathiriyeli enye endaweni ye-composites. Iplastiki kufuneka ikwazi ukungena kwiinkqubo zokuphinda isetyenziswe ngoomatshini okanye iikhemikhali ngaphandle kokuthotywa okubonakalayo komgangatho, okuyivumela ukuba iguqulwe ibe yimveliso emitsha. Kufuneka kubekho urhwebo olusebenzayo lwemveliso imathiriyeli ehlaziyiweyo, eqinisekisa ukuba inokuthengiswa kwaye isetyenziswe ekwenzeni iimveliso ezintsha.

-Ukupakishwa kwe-Mono-material kulula ukuphinda kusetyenziswe xa kuthelekiswa nokupakishwa kwezinto ezininzi. Kuba inohlobo olunye kuphela lweplastiki, inokusetyenzwa ngokufanelekileyo kwiindawo zokurisayikilisha, okukhokelela kumazinga aphezulu okurisayikilisha.

-Ngohlobo olulodwa kuphela lwezinto, kukho umngcipheko omncinci wokungcola ngexesha lenkqubo yokuphinda isetyenziswe. Oku kuphucula umgangatho wezinto ezihlaziyiweyo kwaye kuzenza zixabiseke ngakumbi.

-I-Mono-material packaging ihlala ilula kunezinye izinto ezininzi, ezinokunciphisa iindleko zokuthutha kunye nokukhutshwa kwekhabhoni ephantsi ngexesha lokuthunyelwa.

-Izinto ezithile ze-mono-materials zinokubonelela ngeempawu ezintle zomqobo, ezinceda ukwandisa ubomi beshelufu yeemveliso ngelixa zigcina umgangatho wazo.

Le nkcazo ijolise ekukhuthazeni uqoqosho lwesetyhula, apho ukupakishwa kweplastiki kungalahlwa nje kuphela kodwa kuhlanganiswe kwakhona kumjikelo wemveliso.

Uncedo lwabathengi:Izingxobo zihlala zineempawu ezinje ngeeziphu eziphinda zivaleleke okanye ii-spouts, ziphucula ukusebenziseka lula kwabasebenzisi kunye nokunciphisa inkunkuma.

Izingxobo zeplastiki eziguquguqukayo kunye neefilimu zibonelela ngesisombululo esiguquguqukayo, esisebenzayo, kwaye esihlala sizinzileyo xa kuthelekiswa nezikhongozeli ezomeleleyo.

Ixesha lokuposa: Sep-02-2024